Creating your own Rocket Industrial personal account has many benefits:

Scrap choppers are efficient machines that are used to reduce scrap materials such as metal banding, PET or plastic strapping, bandsaw blades, baling wire, and cable. Unchopped scrap is difficult to handle and poses a hazard to employees while lying around. In fact, the ROI of scrap chopper can typically be justified by reducing just one Workers’ Compensation claim. Here’s everything you need to know about scrap choppers.

How does a scrap chopper work?

Simply introduce the scrap banding into the infeed tunnel of the machine, and the feedworks will grab and pull the material into the path of a rotating knife. The feedworks pulls the scrap until it is all chopped, or until the operator releases the feedworks lever.

Why should I buy a scrap chopper instead of just throwing scrap into a dumpster?

Chopped strapping is more compact and costs less to dispose of. As dumping fees continue to rise, most customers see an ROI in as little as six months by lowering the number of times dumpsters need to be emptied. In fact, customers often a 10:1 scrap reduction since strapping that fills a 20-yard dump box can often fit into just one Gaylord box after being chopped.

How do I know if my company needs a scrap chopper?

If dumpsters or containers collect your banding and often need to be emptied, a scrap chopper can drastically reduce scrap disposal costs and increase operational space. Simple to use, minimal training is needed for employees to operate a machine. In fact, just about any industry can benefit from a scrap chopper, especially the lumber and manufacturing industries.

What are the top benefits of scrap choppers?

Implementing a scrap chopper reduces dumping fees, frees up production space, improves productivity, lowers risk management costs, increases revenue from recycled materials, and strengthens environmental goals.

Which scrap chopper should I buy?

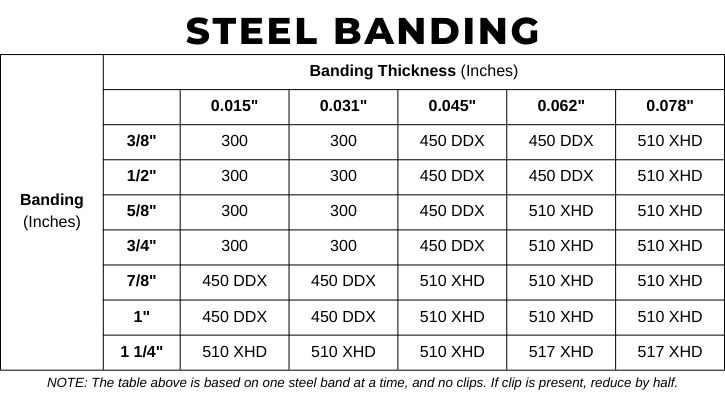

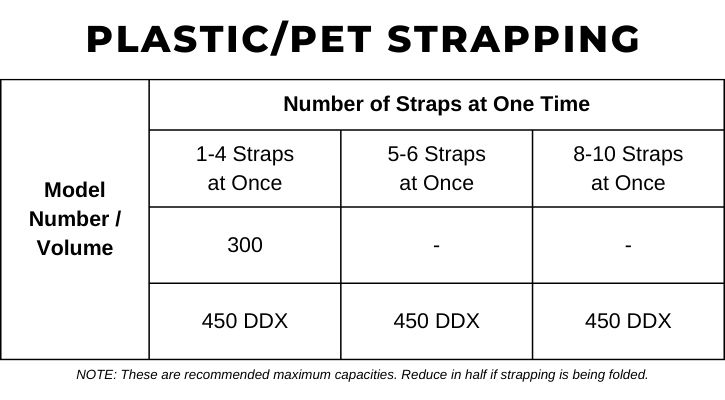

Depending on the strapping material and thickness being chopped, different models of scrap choppers should be used. Use the guides below for reference.

Are there safety features for scrap choppers?

Built-in safety features include a start/stop button, infeed restrictor plate, feedworks safety handle, and lifting lug. Additional protection upgrades include an auto shut-off timer and an exhaust spillway chute.

Can scrap choppers be integrated into existing operations?

There are a variety of accessories for scrap choppers that allow them to be integrated into existing operations. Scrap chopper stands accommodate the most common scrap receptacles and can be used as stand-alone units. Systems can be individually tailored for specific needs and integrated into automatic production lines.

Whether you're in lumber, manufacturing, or any other industry, the ease of use, seamless integration into existing operations, environmental benefits, and substantial ROI make choppers a wise investment.

Strap choppers increase efficiency and provide cost savings to all industries. Contact our packaging specialists to see how these machines can optimize waste reduction, cut expenses, and enhance your industrial operations.