Creating your own Rocket Industrial personal account has many benefits:

Drop impact tests measure the capability of a container to withstand the sudden shock resulting from free fall.

An incline impact tests simulate rail car handling, sudden breaking, and pallet marshaling.

A compression test simulates the stacking of unitized loads during storage and shipment to make sure the packaging can withstand various compression forces.

A forklift handling test will simulate rotational flat, edge, and corner drops as well as the ISTA forklift handling road course.

All tests performed in the lab are to ISTA and ASTM standards where applicable. Rocket Industrial has also developed a unique set of tests specific to the packaging industry.

Environmental testing determines if the package and product can withstand temperature changes, humidity, and other known environmental factors in the product's distribution environment.

Used to determine the water vapor transmission rate of permeable and semipermeable materials such as paper, films, and fiberboards.

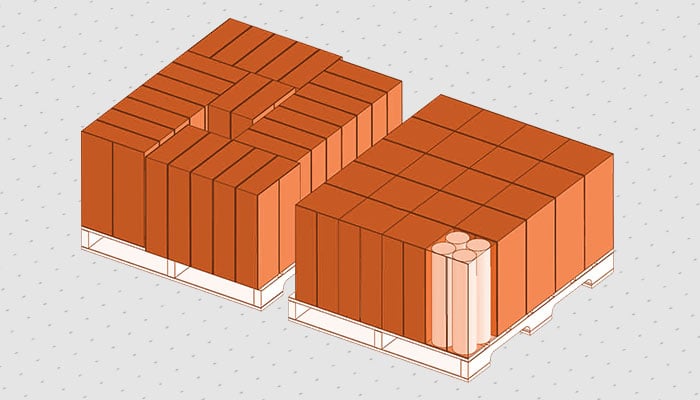

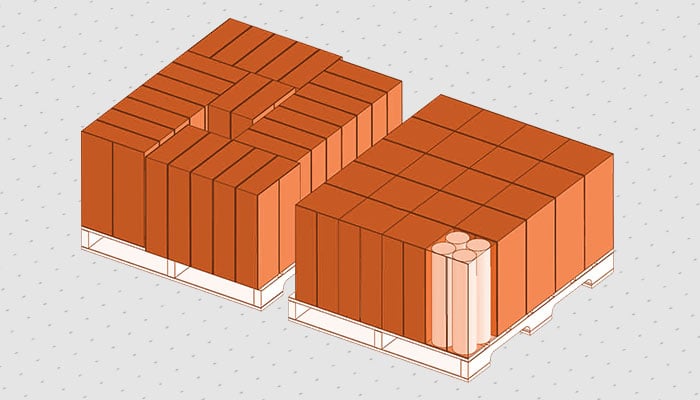

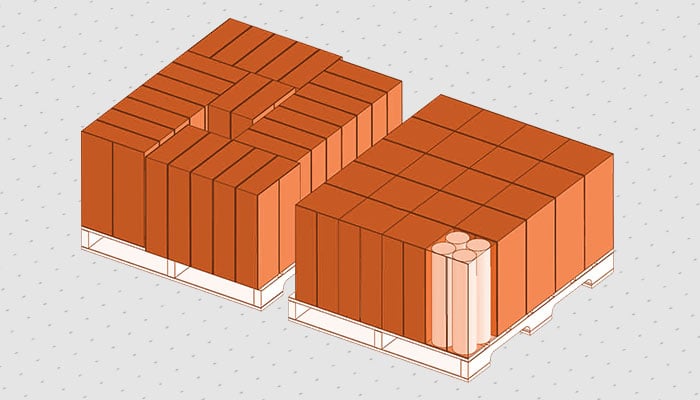

Load containment is a measurement of the force required to cause a shift in your pallet load.

A puncture test is used to show the amount of force needed for an object to puncture through stretch wrap film.

Tension strength testing measures the force required for a material to break under tension.

Secondary packaging and your pallet pattern form a relationship that can have a big impact on your shipment process. Using specialized software, we analyze your package and pallet pattern stack to reduce any space you may be shipping. Completing a project could result in:

What standards are your tests performed to?

All standard tests performed in our lab are done so in accordance with ISTA (International Safe Transit Association) or ASTM (American Society for Testing and Materials) regulations. Custom tests are developed by our engineering team to be done in accordance with ISTA and ASTM whenever possible.

What are the first steps taken in a project?

Most projects start with a discovery meeting between you and our packaging lab team. In the meeting, we will want to learn the challenges you face and set goals for a successful project.

How long do projects take?

Project lengths can vary based on what is required for completion. We will always communicate the anticipated schedule throughout the entire process.

Can I send you our typical product pallet and you analyze the packaging configuration?

Yes, sometimes we refer to this as a Pallet Pit Stop. We run our standard tests on your secondary packaging then provide you our recommendations.