Creating your own Rocket Industrial personal account has many benefits:

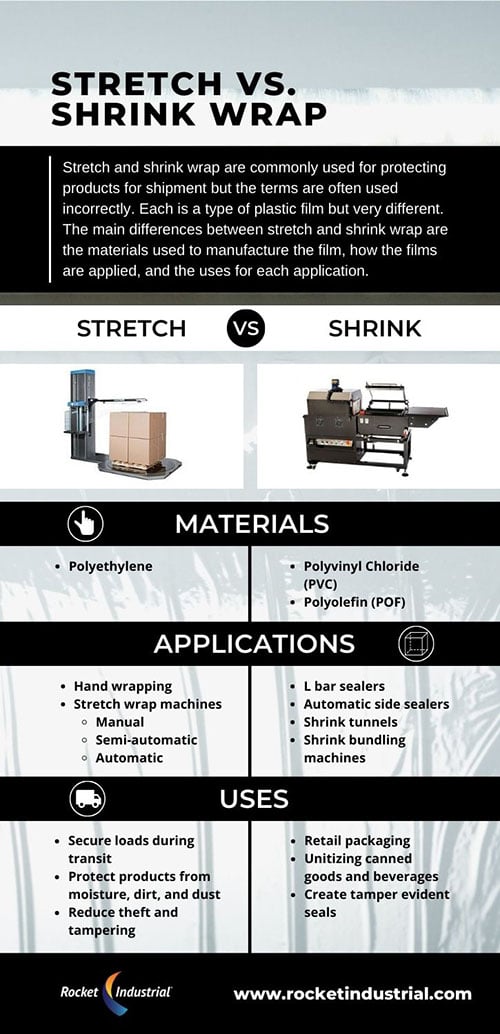

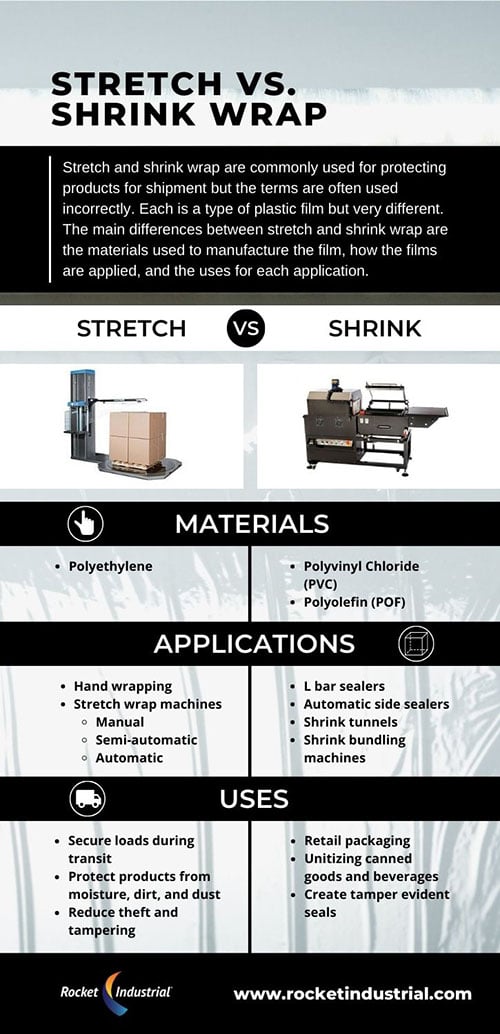

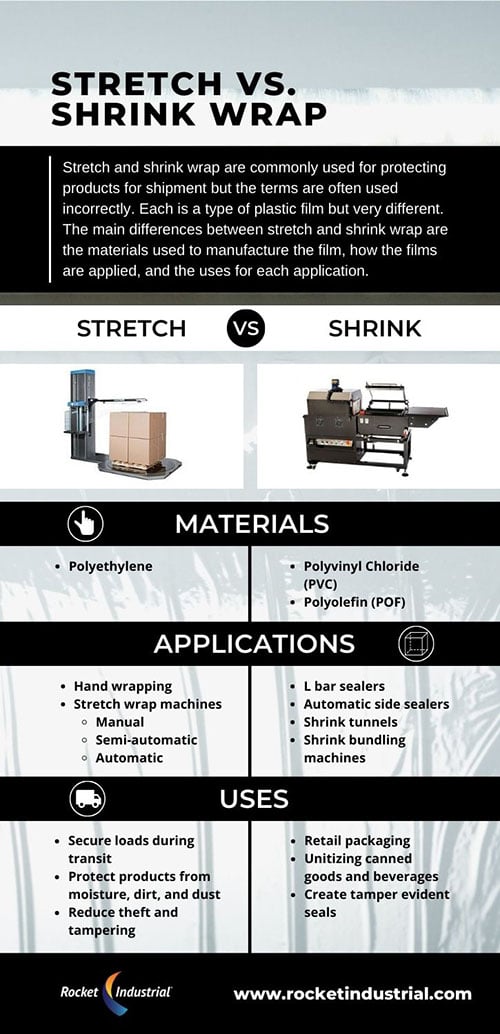

The terms stretch wrap and shrink wrap are often used interchangeably but are very different. Both are commonly used for protecting products for shipment, but the two materials are not the same. Here’s a breakdown of the differences between the films and what applications they are used in.

Stretch Wrap

Stretch wrap is a plastic film that can be applied by hand or machine to secure boxes or products on a pallet. It’s most commonly made from polyethylene plastic and adds extra protection for products during the storage and transportation processes.

Stretch wrap is typically clear to see what’s on the pallet easily but is available in various colors, such as blue or green, to be quickly identifiable. There are two different types of stretch film, blown and cast, which refers to the way the film was manufactured. Each type of stretch wrap is available in a wide variety of lengths, widths, and gauges to accommodate specific load shapes and weights.

Hand Stretch Wrapping vs Machine Stretch Wrapping

Stretch wrap can be applied either by hand or by using a stretch wrap machine. Hand-grade stretch film is shorter and lighter to be applied manually around a pallet. A roll of hand stretch film is typically 1,500 feet long and weighs between 5 to 9 pounds.

Machine wrap rolls are longer and wider than hand rolls and are applied with a pallet wrapping machine. Rolls of machine film can weigh over 100 pounds and range from 20" to 80" in width. Stretch wrappers are recommended if you are wrapping more than 15 loads per day as they help reduce film waste and labor costs, and increase overall packaging efficiency.

Shrink Wrap

Shrink wrap is the tight, clear plastic film that comes wrapped around consumer products where appearance is important, such as water bottles, food, books, toys, and other retail items. The film is an extremely versatile and durable polymer material and is available in a variety of thicknesses, strengths, and shrink ratios.

There are two main types of shrink wrap: Polyvinyl Chloride (PVC) and Polyolefin (POF). PVC is less expensive but is not widely used due to the health dangers it poses during creation and disposal. PVC is created from a combination of carbon, hydrogen, and chlorine, which gives off a strong, harmful order when heated. It's also a #3 recyclable material meaning it's unable to be recycled in most cases.

Polyolefin is by far the most commonly used of the two and is the preferred shrink film. This type of shrink film is extremely durable, clear, and an FDA-approved food material. POF shrink wrap is available in thicknesses ranging from 35 (.35 mil) to 100 (1 mil) gauge. It's created from 100% recyclable materials and is more resistant to temperature changes.

Shrink Wrap Equipment

Shrink film can be applied in a variety of ways, such as using heat guns, L bar sealers, and heat tunnels. A shrink wrap machine sealer closes the open ends of the shrink film, then the heat source applies heat to the material to shrink it down to the product. Low-output operations typically use heat guns or tabletop heat sealers while high-output productions use heat tunnels or L bar sealers.

Stretch wrap and shrink wrap have different uses and cannot be used in place of each other. Stretch film wraps protect pallets of products for shipment and storage, while shrink film wraps protect consumer goods for storage and shelving. Contact our packaging specialists for assistance in selecting the right type of film for your packaging application.