Creating your own Rocket Industrial personal account has many benefits:

Stretch wrap, or stretch film, is one of the most frequently used materials in shipping and warehouse environments. It’s used to hold boxes and products together on a pallet for transportation and storage. Navigating through the various types of films and knowing what’s best for your application can be tricky. We’ve put together this usage guide and answers to the most frequently asked stretch wrap questions to help.

Stretch wrap comes in different thicknesses, known as gauges, as well as different widths. Roll widths ranging from 12” to 18” are typically classified as ‘hand-grade’ film while larger roles, most commonly of 20” widths, are called ‘machine-grade’ and for use with a stretch wrapping machine.

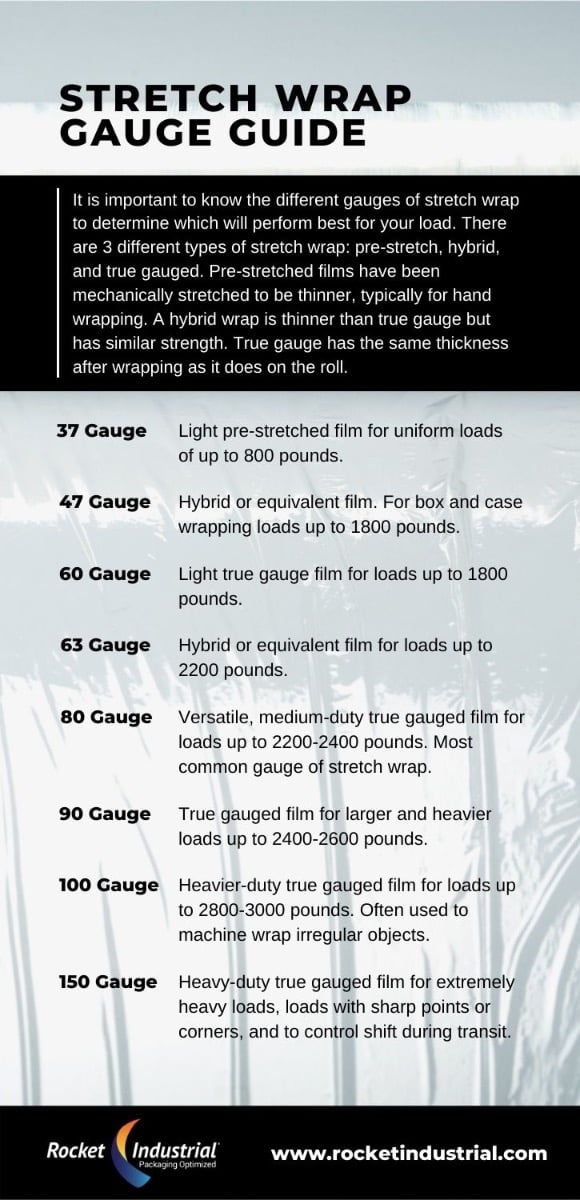

Stretch wrap comes in gauges ranging from 37 to 150, with 63 to 80 being the most commonly used. To choose the correct gauge, you need to consider a few factors:

• Shape of the load - Irregular shaped loads will require more holding power from a stronger wrap than a uniform load of same sized boxes.

• Weight of the load - The heavier the load, the stronger the stretch film will need to be. Refer to the chart below for some general weight and application guidelines.

Pre-stretched film is a type of stretch wrap film applied by hand that has been stretched near its breaking point and then wound onto rolls. These films have been mechanically stretched to around 90% at the factory, resulting in thinner gauges than standard stretch film.

The main benefits of pre-stretched hand wrap are that it’s easier to apply, lighter, and offers double the strength at half the thickness of standard wrap. This leads to more efficient use of film, better load stability, fewer damages, and less waste.

Opaque stretch film is often used to conceal products or protect contents from theft. It also helps to protect products from UV, so is used in applications where shipments will be stored outside short term.

Stretch film can also come in a variety of colors. These films are great for color-coding products. Green is often used on eco-friendly products or to show products have the green light and are ready to ship.

It’s estimated that only around 5% of stretch wrap is recovered in the U.S. after use. Stretch film is typically made with linear low-density polyethylene (LLDPE), which falls under category four of recycling programs, but due to the thin nature of the plastic it’s not able to be recycled in a curbside bin. It requires a special process to be washed, shredded, and extruded. Check with your local recycling programs to see if there is an affiliate near you that can help with plastic film recycling.

Related: Are you using too much stretch film? Use our Stretch Wrap Efficiency Calculator to find your optimum stretch levels.

Rocket Industrial carries a range of stretch wraps and films in a variety of gauges, widths, colors, and types. If you’re not sure which wrap is the best for your application, contact a packaging specialist for guidance.