Creating your own Rocket Industrial personal account has many benefits:

Choosing the correct packaging tape for your specific application can reduce product damage, decrease material waste, and increase efficiency. Corrugated cardboard boxes sealed with the proper tape maintain integrity during transport. Various factors go into the consideration process such as application method, content weight, environmental factors, distribution conditions, tape quality and grade, and adhesion surface/substrate. Using the wrong tape can be a costly mistake, so we've put together this guide to help you select the best tape for your needs.

Carton sealing tape comes in various widths, lengths, thicknesses, materials, and strengths, and it is important to select one that will properly seal your boxes.

Length & Width

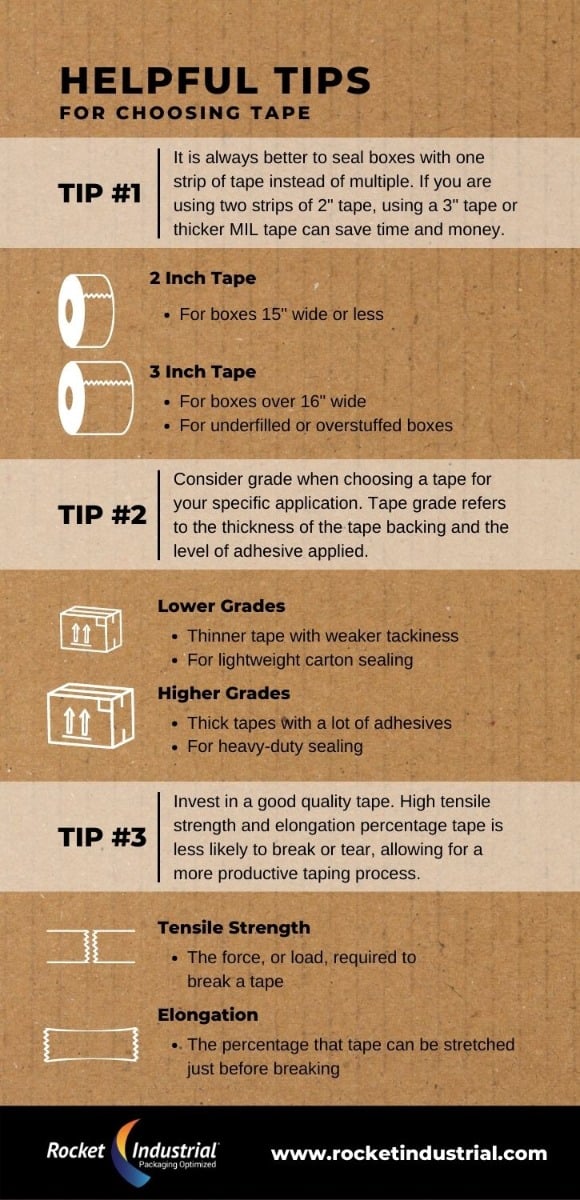

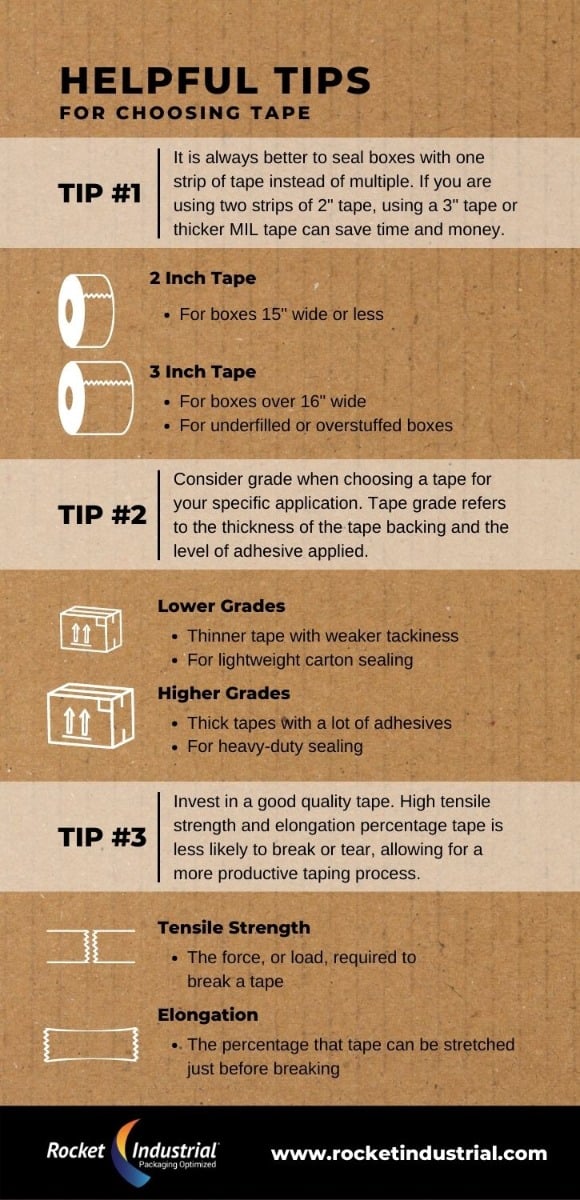

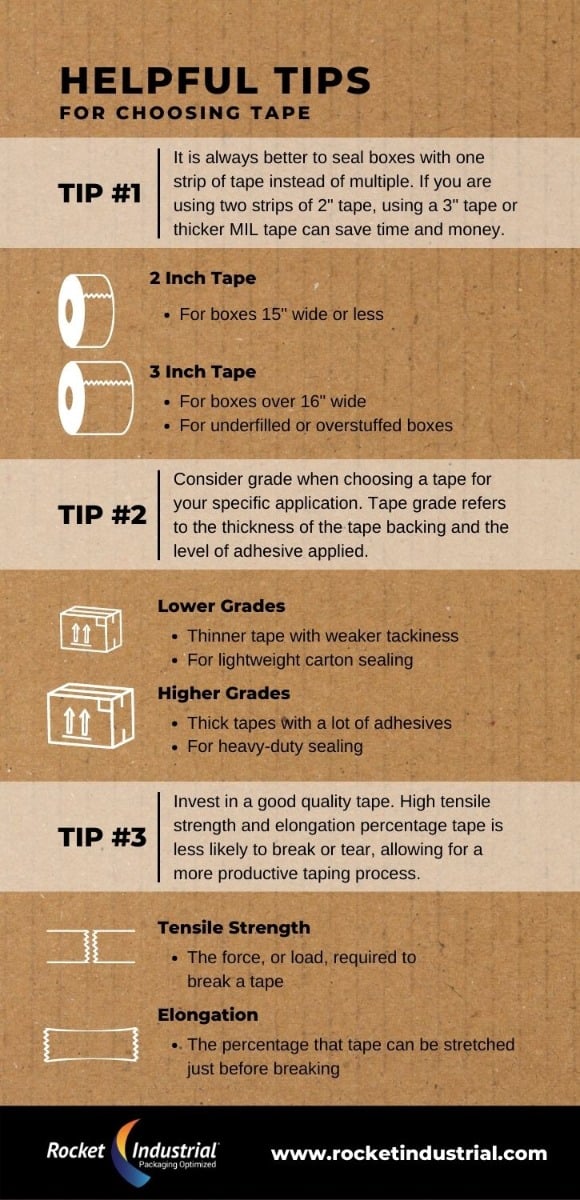

Sealing boxes with one strip of tape instead of multiple is always better. If you are using two strips of 2-inch tape, using 3-inch tape instead can save time and money. Hand carton sealing tape typically comes in 55-yard or 110-yard rolls. Machine carton sealing tape ranges from 1000-2000 yards in length.

We typically recommend using 3" tape for boxes over 16" wide. You may also want to consider a 3" tape if you are using 2 strips of 2" tape to seal your boxes.

Tensile Strength & Elongation

Tensile strength is the force required to break a tape and elongation is the percentage a tape can be stretched just before breaking. Investing in tape with high tensile strength and elongation allows for a more productive taping process.

Adhesives

Natural rubber adhesives are very flexible, even in low temperatures as low as 0°F. Appears brown in color, but is clear.

Hot melt tape, also known as synthetic rubber, has quick stick bonding and long-lasting adhesive properties for packing overstuffed cartons or boxes made of high recycled content. Provides a more consistent seal so is used in most shipping situations.

Acrylic tape provides environmental resistance and has a faster setting time, making it ideal for long-term storage in varying temperatures and lightweight box sealing.

| APPLICATION PROPERTIES | ACRYLIC | HOT MELT |

| Rough/Recycled Corrugated Boxes | Good | Very Good |

| Printed Cartons | Good | Very Good |

| Adhesion in Cold | Very Good | Poor |

| Operating Range (Temperature) | 32° - 140° | 45° - 120° |

Thickness

The weight and dimensions of a box help determine the mil thickness of box sealing tape that is needed. The typical rule is that the heavier and larger the box, the thicker the tape will be needed. Additionally, tapes with a thickness between 1.6 mil and 1.9 mil are designed to be economical while still providing great performance.

| BOX WEIGHT | LENGTH WIDTH HEIGHT | MIL THICKNESS |

| 0 - 20 lbs. | 0 - 40 inches | 1.6 Mil - 1.8 Mil |

| 20 - 35 lbs. | 0 - 50 inches | 1.8 Mil - 2.0 Mil |

| 35 - 50 lbs. | 0 - 60 inches | 2.0 Mil - 2.6 Mil |

| 50 - 65 lbs. | 0 - 80 inches | 2.6 Mil - 3.2 Mil |

| 65 - 80 lbs. | 0 - 100 inches | 3.2 Mil - 3.5 Mil |

**For package dimensions/weights not listed on this chart, contact our packaging specialists to help you choose the proper tape for your application.

Best Economical Tape

The BestPack BG16 series hand and machine tape is a great entry-level tape that meets most packing needs and is fairly priced.

Best Cold Environment Tape

The Vibac 6200 medium-duty tape, IPG 7151QT cold temperature tape, and 3M 311+ carton sealer tape are designed for cold environments. These tapes can be applied and stored in low-temperature environments, and come in both hand and machine-length rolls.

Best Industrial Tape for Recycled Corrugate

The BestPack BG20 series tape and 3M 371+ packaging tape are formulated with high tack adhesive properties to ensure the highest security when sealing corrugated cartons.

Proper tape application is essential for sealing boxes. Whether you are hand sealing or using a case sealer, use these tips to ensure proper sealing.

Hand Sealing

Machine Sealing

Our team of packaging experts can help you find the best carton sealing tape for your needs. You can also utilize our Packaging Test Lab for a data-backed solution. Our lab can perform tests on a tape's shear adhesion, tensile strength, elongation, and peel adhesion while putting your actual packaging through simulated situations. Contact one of our packaging specialists to get started.