Creating your own Rocket Industrial personal account has many benefits:

An aquatic life distributor came to Rocket Industrial looking for a sustainable alternative to the EPS foam packaging that was being used for shipments. The new packaging needed to have the same temperature-controlled performance to keep aquatic life safe during the transportation process.

Goals:

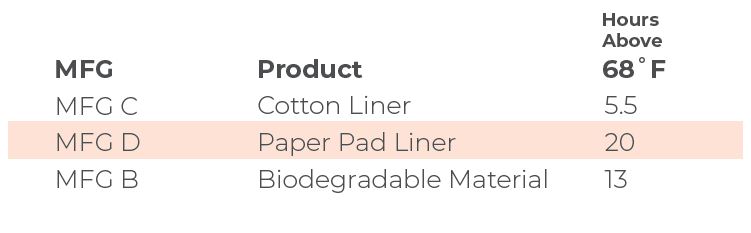

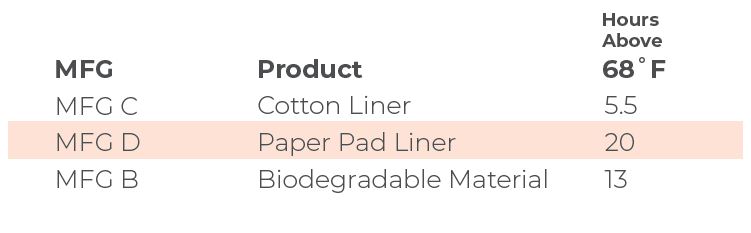

Testing at 90°F (Temperature sensor in a water bottle to simulate fish conditions)

The client confidently implemented paper insulated packaging to replace the foam-lined boxes. The paper liner performed just as well during transport, kept the aquatic life safe, and met the client's sustainability requirements.

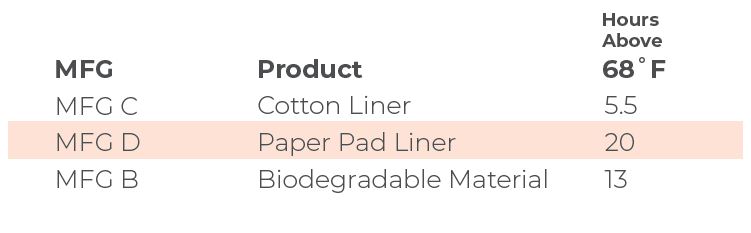

Testing at 40°F (Temperature sensor in a water bottle to simulate fish conditions)