Creating your own Rocket Industrial personal account has many benefits:

A client specializing in providing functional work and retail environments contacted our packaging specialist. Their current packaging was working, but it was very time-consuming to construct. The discovery meeting uncovered how they were building similar wood crates by hand for each product with minor differences crate to crate.

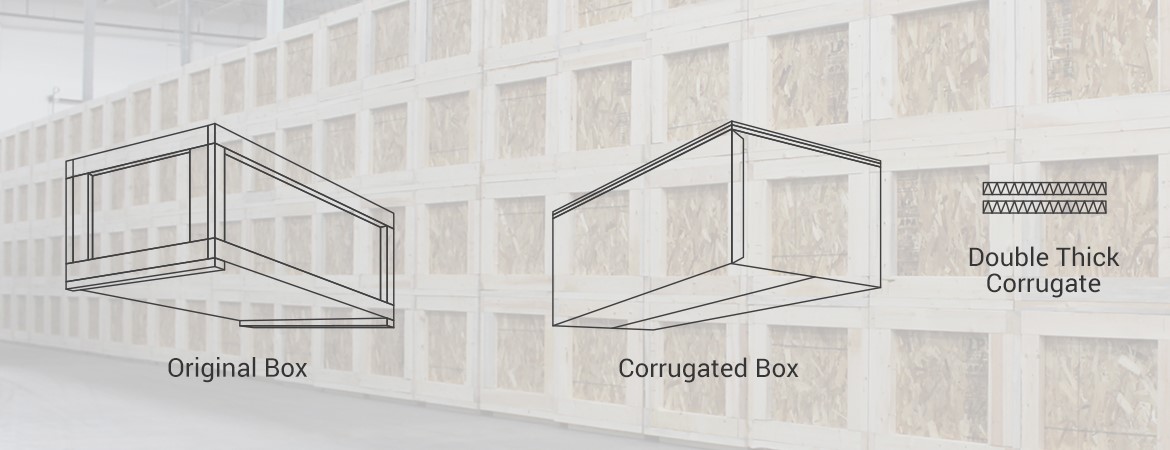

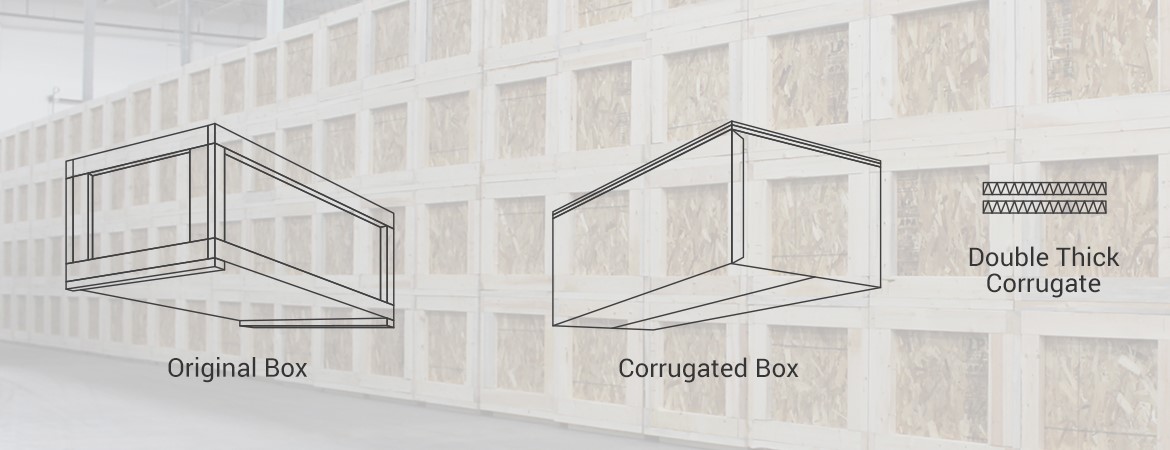

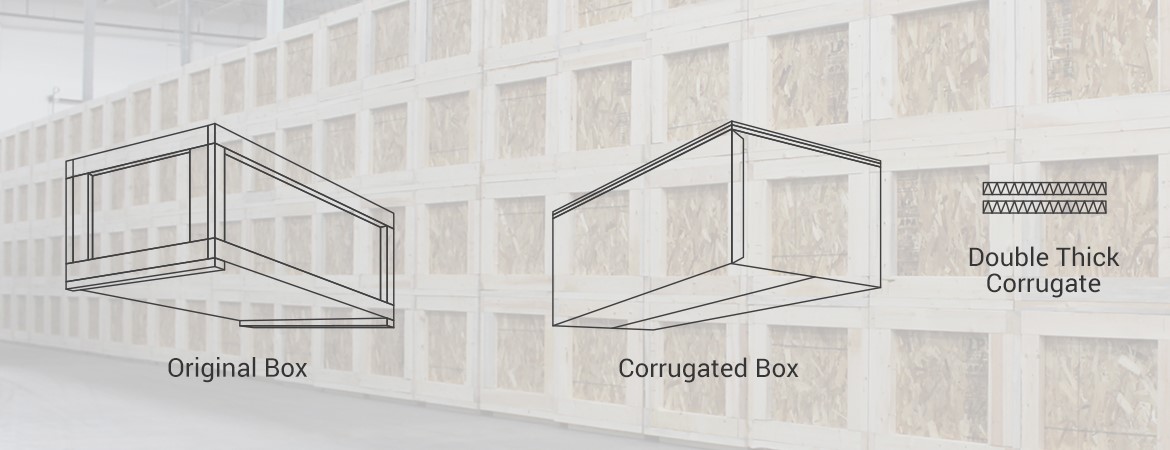

Our team was able to develop, prototype and test a new crate solution. A two-piece corrugated container with specially designed wall construction was created. The application of dual walls allowed the corrugated material to stand strong as a replacement for the previous wood. The sides easily folded out and dropped over the product, and the top was form-fitted to create a clean seal.

The new corrugated crates are much quicker to assemble, require less physical effort, and cost less overall.

“The Rocket Industrial packaging specialist taught us the best practices when it came to packaging … We are now delivering a better packaged product and making it easier for our employees.”

– Tarra G, Project Executive

Since the completion of the crate project, we have since brought serval other packaging solutions to this same client.

We can get you started or answer any question you have.