Creating your own Rocket Industrial personal account has many benefits:

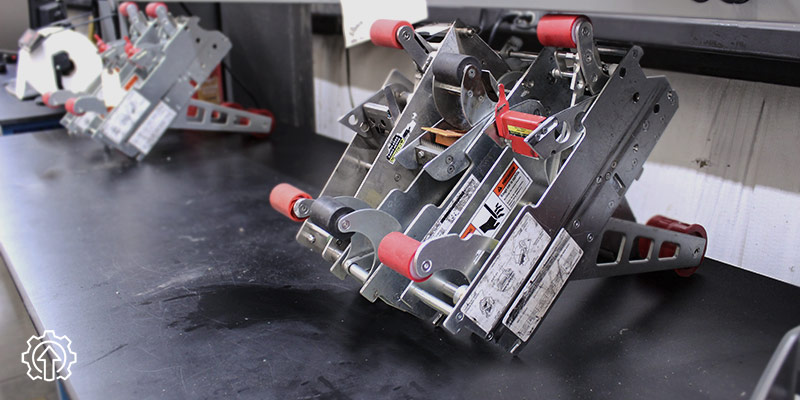

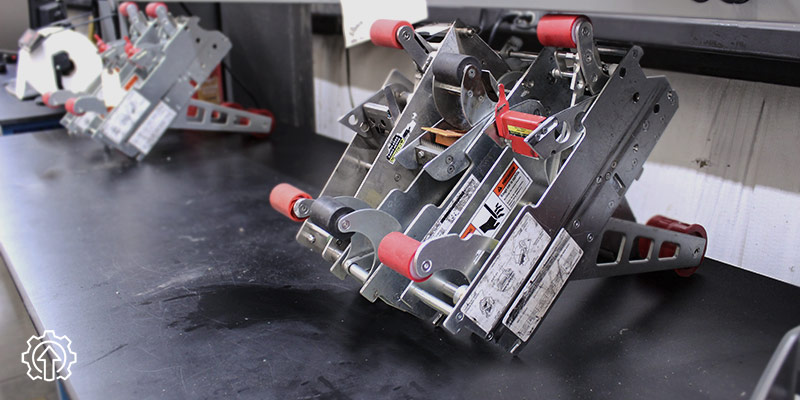

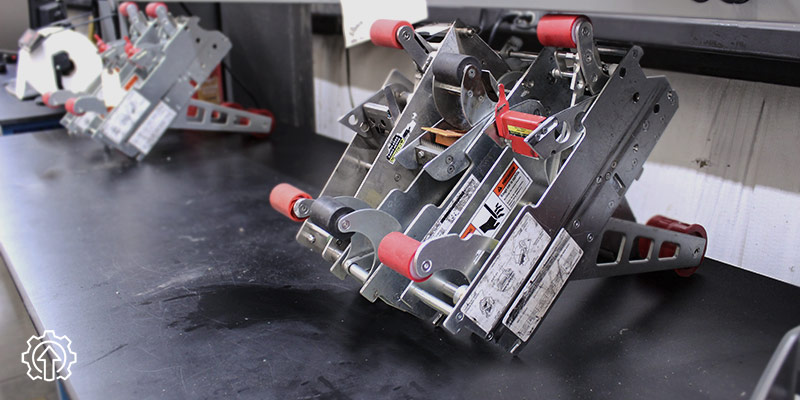

It only takes a few minutes of downtime for a facility to feel the costly effects, but preventative maintenance can ensure this doesn't happen. Certain equipment parts are designed to wear out to prevent damage to the critical elements of the unit, and replacing these parts at the correct interval is the core of preventative maintenance.

Preventative maintenance reduces machine failure and maximizes the total lifespan of your equipment. Finding skilled technicians and the time to implement an effective program can be challenging. Our team of service technicians can keep your facility up and running through a proactive maintenance visit that fits into your operations schedule.

Choose from a Basic or Pro plan which allows customization based on your operation.

| Basic | Pro | |

| Quarterly Site Visit | X | X |

| Training for In-House Team | X | X |

| Virtual Installation Support | X | X |

| Internal Inventory on Your Parts | X | |

| Unexpected Repair Included | X | |

| Prioritized Virtual Service | X | |

| Custom Site Visit Intervals | X | |

| Reduced Rate Supply Agreements* | X |

*Depending on your supply agreements with Rocket Industrial, a Gear Up Preventative Maintenance Plan could be available at no additional cost. Speak with your Rocket Industrial sales representative to learn more.