Creating your own Rocket Industrial personal account has many benefits:

One small change can result in some serious savings! Packaging optimization seeks to eliminate shipping air, reduce packaging consumption, and find the happy medium between product damage and packaging cost. Our packaging engineers analyze your overall packaging materials, methods and systems to provide data-driven recommendations based on your goals.

What is your rate of product damage and packaging failure complaints?

If you have known issues with high product damage and/or packaging failures we can help you find a better protective solution or material to keep your customers happy. On the other hand, if you’ve been shipping the same product the same way for several years without issues, we may be able to find several improved packaging optimizations that can reduce your overall packaging costs.

Have you ever wondered how much air you're shipping?

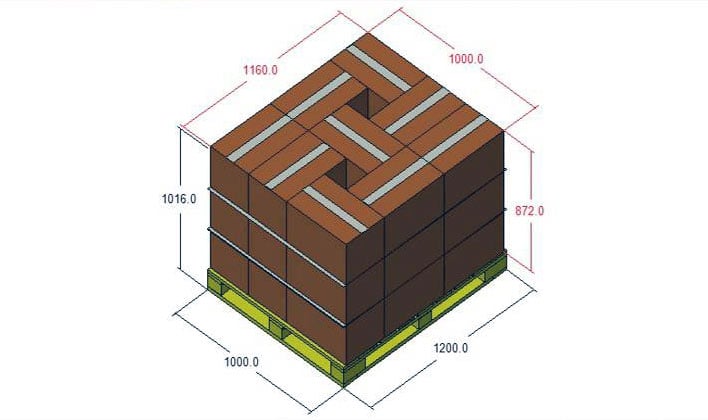

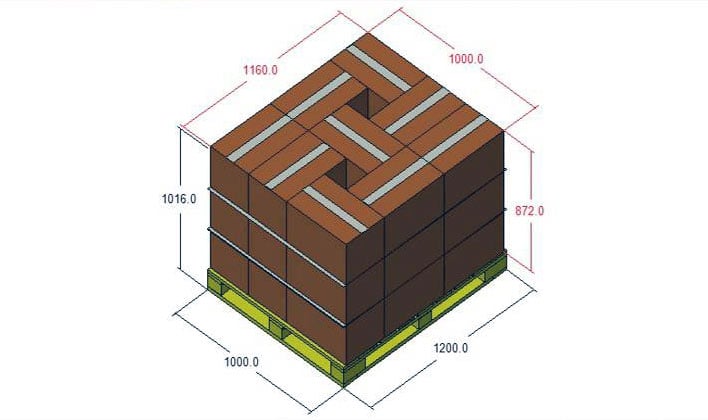

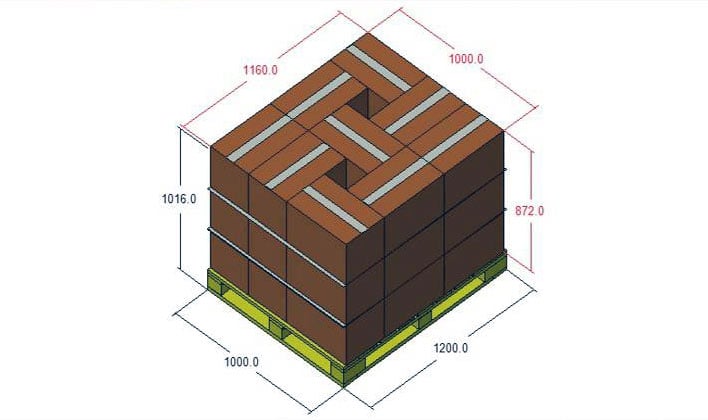

Sometimes shipping is air is unavoidable without changing the design of the product. However, we can help you determine exactly how much air can be safetly removed and suggest simple changes such as improving your dimensional weights, optimizing box sizes and pallet pattern cube efficiencies.

If you’re looking for a significant costs savings and reduction in packaging materials, analyzing your stretch film consumption is the place to start.

We test films at various prestretch levels to find ways to improve your existing stretch wrap performance.

We measure the following:

Using specialized software, we can determine optimal case packing, palletizing, and shipment stacking patterns to minimize product damage and save on costs.

Our findings will help you:

We can calculate the maximum stacking strength and determine the optimal package size for your product to improve your bottom line.

We will help you:

Let us look into your packaging systems and determine if you’re using optimal materials for max protection and cost efficiency.

We can help you find optimal stretch films, corrugated and paperboard strength rating, tape, and poly film down-gauging.