Creating your own Rocket Industrial personal account has many benefits:

Routine maintenance is required to keep case sealer tape heads running at top operating performance since breakdowns can be extremely costly. Save money and extend the life cycle of your tape heads by following our maintenance checklist and troubleshooting guide.

Recommended Maintenance Tools

Being proactive in your case sealer maintenance schedule allows you to find a solution to problems before they begin to affect production. By routinely checking key parts and components, you’ll be more likely to notice when something doesn’t seem right or is beginning to wear.

Download this 7-Point Tape Head Maintenance Checklist to share with your operators and maintenance team. We recommend checking these areas daily to improve packaging performance and reduce issues associated with inadequate taping.

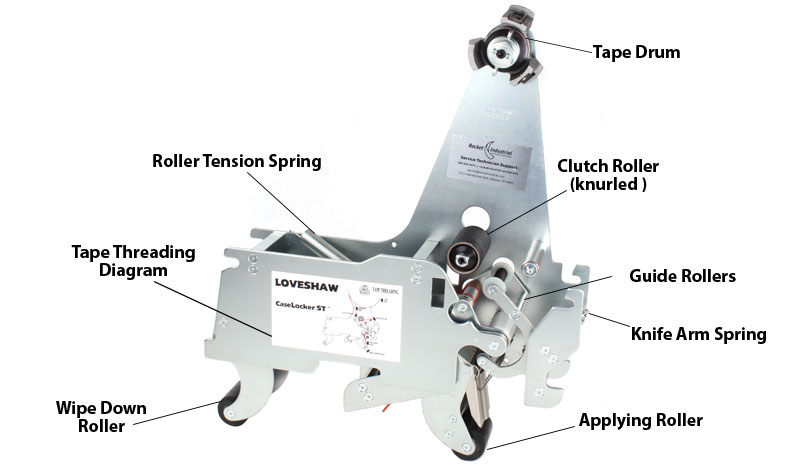

Adjust main spring – Check the main spring for tension and ensure it isn’t too weak or too strong. If it’s too weak, it will not wipe down the tape. If it’s too strong, it will deform your box.

Adjust exit tape roller – Make sure the roller moves freely in both directions. Keep the roller clean and remove any old tape pieces.

Adjust tape roll – The tape roll should only be adjusted enough to keep the roll from backlashing. The roll should be able to spin approximately a quarter of the way around.

Adjust tape tension – The amount of tension applied to the tape should be enough so that it can be cut. If the tension is too high, the tape will snap back onto itself. Make sure the sticky side of the tape is on the roller.

Set tape finger position – The tape fingers need to be touching the tape. This gives the tape enough strength to stand up.

Adjust entry tape roller – The roller should move freely in one direction. The tape should be positioned at mid-roller. If the tape is too long, the tension will be too low. If the tape is too short, the tension will be too high. Keep the roller clean and remove any old tape pieces.

Blade maintenance – Check the blade for sharpness and make sure it is clean. Put a little bit of oil on the blade. (Mineral oil stops adhesive from sticking to blade)

Case sealers are used every day to apply carton sealing tape to each box uniformly and securely, ensuring that each case is sealed correctly. When this doesn’t happen, cases will pop open, creating more work, returns, and unnecessary expenses. These common tape issues can typically be resolved by some minor adjustments to the tape head components:

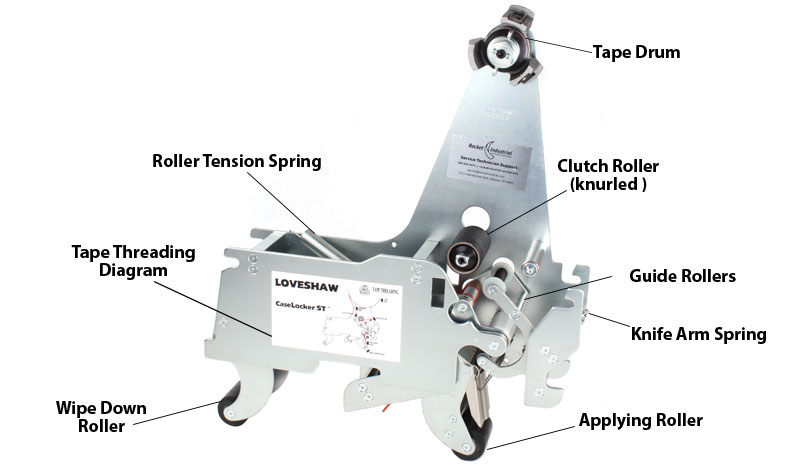

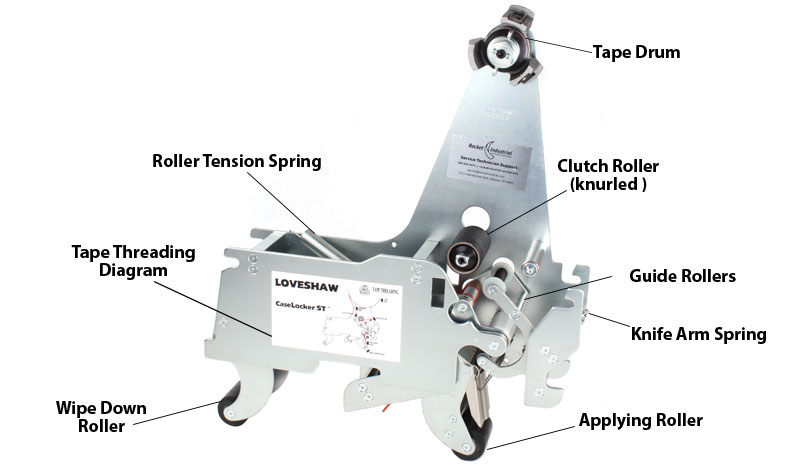

Stretched tape – When the tape is applied too tightly on a box, it will stretch and the adhesive will not be secure on the overlap. If the tape seems to be stretching excessively, first verify that the tape is properly threaded. Then adjust the tape tension knob counter-clockwise enough to decrease tension. You may also need to check the rollers that are coming in contact with the tape to make sure they are rolling freely.

Wrinkled tape – When the tape is applied too loosely on a box, it will wrinkle and the blade may not be able to make the right cut. Again, verify that the tape is being properly threaded first. Then adjust the tape tension knob clockwise to increase tension and check the rollers’ tension as well. If the issue persists, check to see if there is a buildup of adhesive on the rollers that is restricting motion. You may also need to clean or replace the knife blades if the tape is not being cut cleanly.

Off-center tape – This occurs when the tape head is applying the tape to one side or the other of the seam due to improper alignment. Check the machine’s alignment first before making any adjustments to the tape head. If the machine’s alignment is centered and checks out fine, you will need the adjust the tape roll hub, moving it slightly left or right as needed to remedy the problem.

Short tape tails – This happens when a limited amount of tape is applied to the leading or tail end of the box. This can usually be remedied by adjusting an incorrectly set roller or loosening the tape tension. There could also be an issue with the knife blade settings. Check your equipment manual on how to safely and properly adjust the blade height.

*Always beware of the tape applicator’s sharp blade edges and power down before servicing the machine to prevent injury.

**If you are continually facing these problems with your machine, there may be an underlying issue that will require a trained service technician to diagnose and fix.

Contact us to learn more about our tape head exchange or repair program. We also stock the most common case sealer repair parts, browse our case sealer parts online or fill out a service request form to contact a service technician for assistance.