Creating your own Rocket Industrial personal account has many benefits:

A fast growing beer and liquor distributor has been expanding rapidly and their current stretch wrapping process was creating bottlenecks. They were using motorized pallet jacks with 96” forks to build and haul 3 pallets at a time to their stretch wrappers. The operators would then have to unload and wrap each load individually with a combination of rotary stretch wrappers and turntable wrappers. The wrappers created bottlenecks that pushed deadlines back and made shifts longer. As the company expanded they needed a solution to get all of their trucks loaded and ready to go for 5 a.m. deliveries.

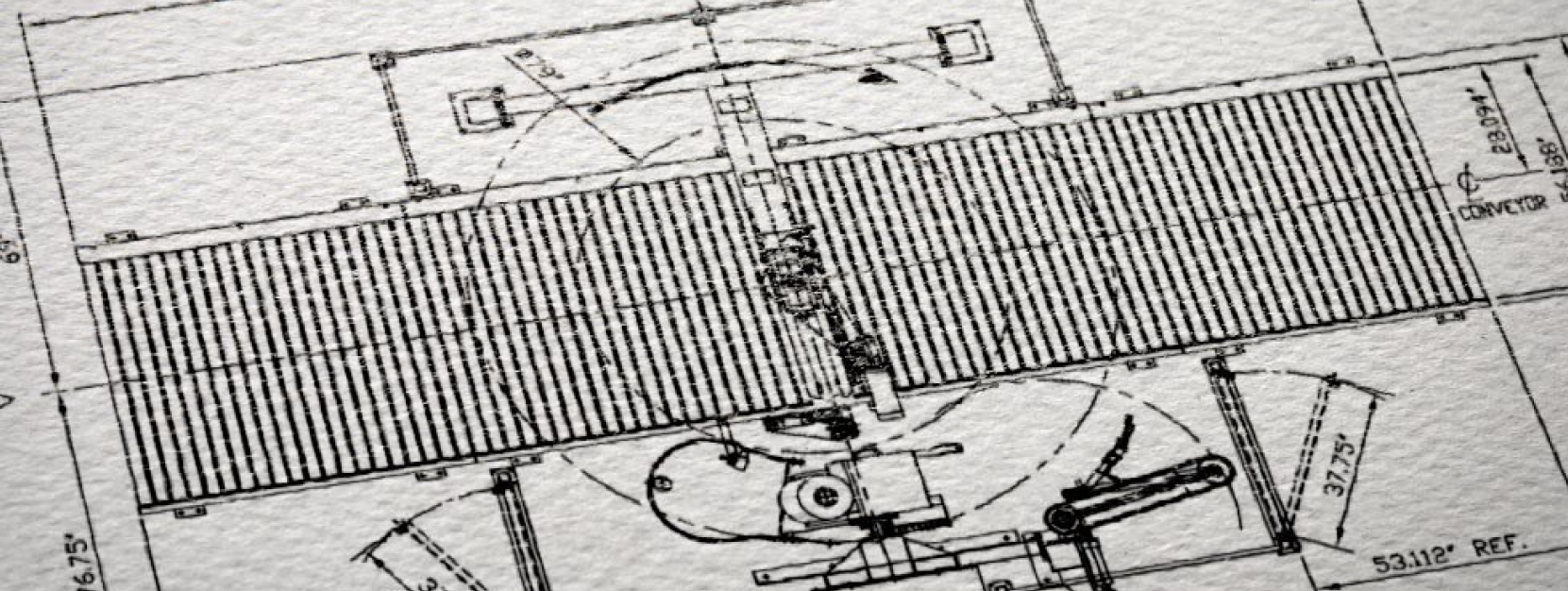

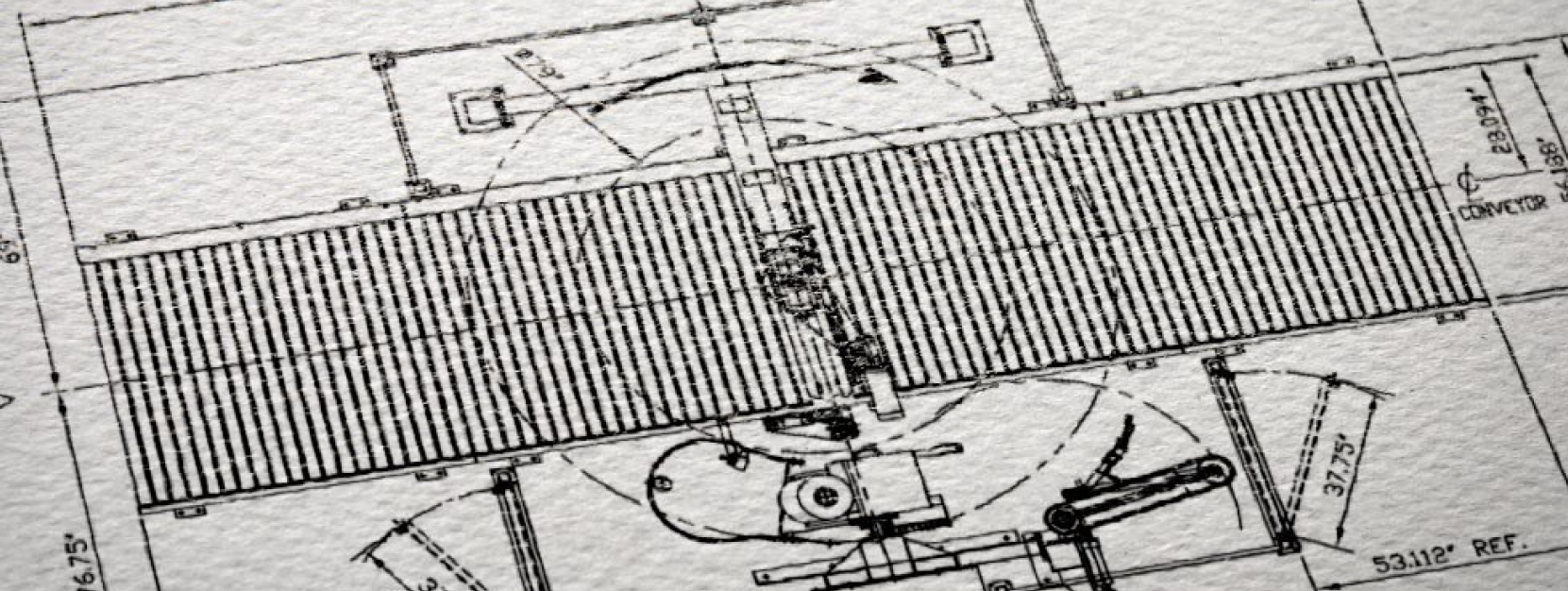

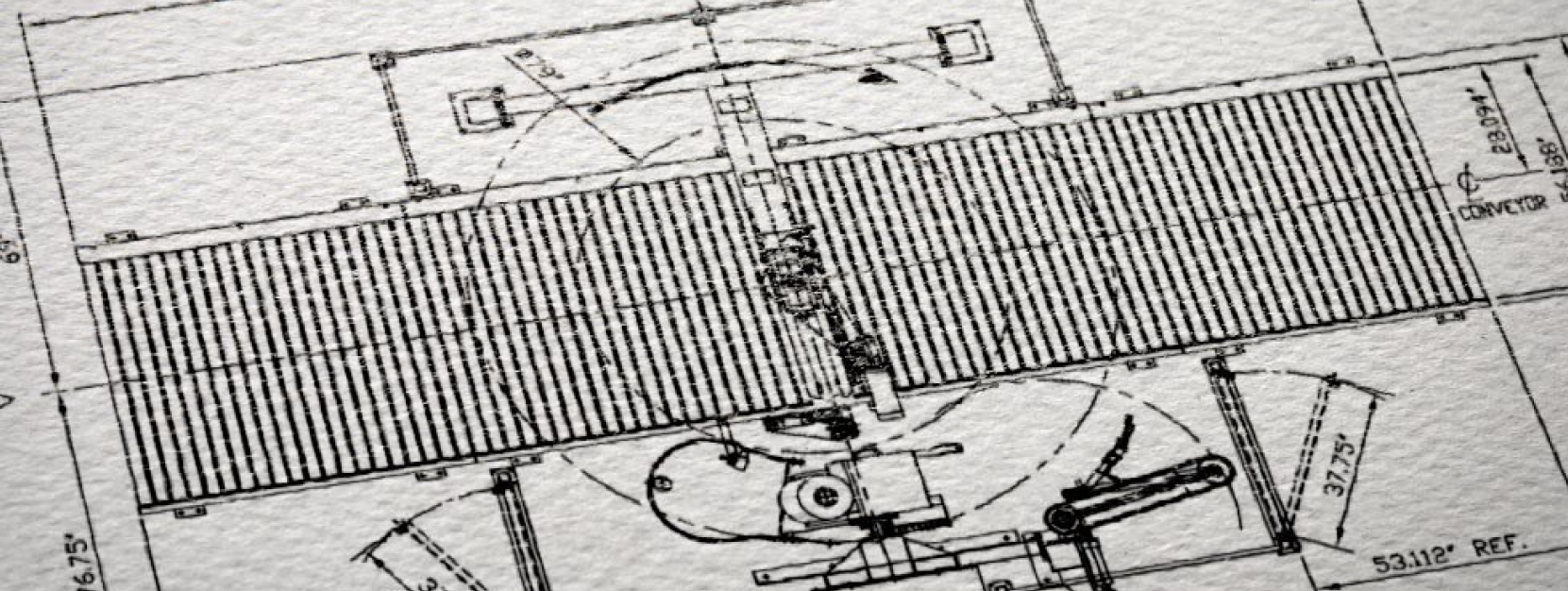

Rocket Industrial partnered with Cousins Packaging to develop an overhead automatic stretch wrapper with a drag chain conveyor. This specialty designed wrapper allows the operators to place all 3 pallet at ground level; the drag chain conveyor then pulls and separates each pallet to be wrapped. The Cousins 4100-45-OHA performs the following in one automated line:

By installing two of the Cousins wrappers this facility has the ability to wrap 900 loads in a 10 hour shift. This packaging automation upgrade has decreased wrap times by over 30% and allows timely loading of all their route trucks.

This project was so successful, that it was also featured in Packaging World.