Creating your own Rocket Industrial personal account has many benefits:

A premier manufacturer of custom injection molded components looked to Rocket Industrial for an automated solution to minimize human contact and meet the demand for packaging face shields during the COVID-19 pandemic.

The facility was hand loading face shields into poly bags and manually applying labels. As production volume increased due to COVID-19 demands, so did the number of employees needed and time spent packing and shipping.

A faster, automated solution was needed to increase packaging speed and allow for social distancing on the packaging line.

Rocket Industrial studied the current workflow, utilized our vendor network, and held conference calls to determine how we could reduce human contact and automate this manufacturer’s packaging line.

Rocket Industrial partnered with Sharp Packaging to install an automated bagging machine that eliminated the slow, costly process of handloading face shields into poly bags. Through consultation, the correct poly bag size was chosen to achieve optimal machine performance. Additionally, an automatic label applicator was utilized to streamline the packaging process.

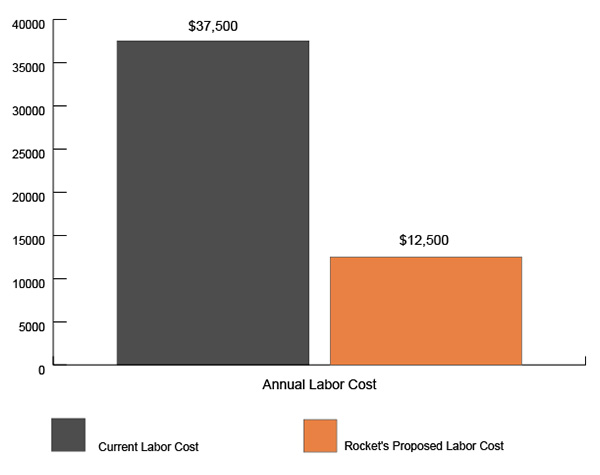

By installing two of Sharp’s bagging machines, and implementing a label applicator and conveyor system, this premier manufacturer can disperse their workforce by requiring four fewer workers on their packaging line.

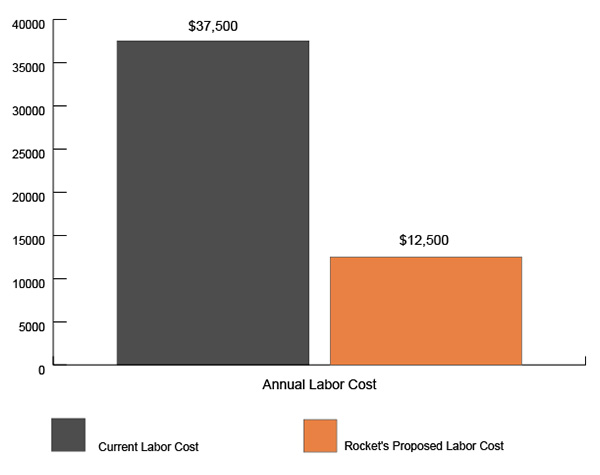

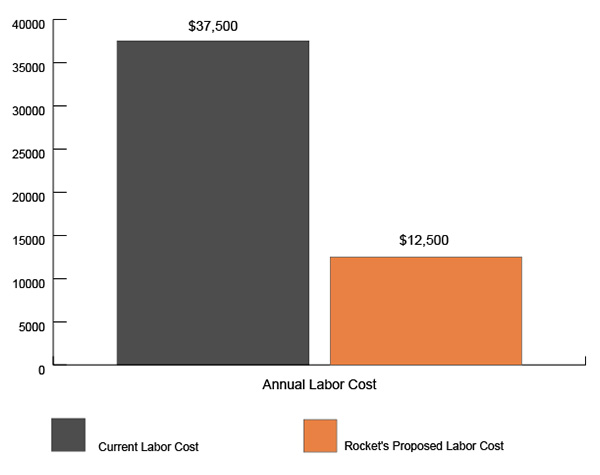

This packaging automation upgrade has decreased labor costs by 33% and allows the timely loading of face shields with reduced human contact.

Start enjoying the long-term benefits of our social distancing solutions by connecting with our sales reps for a video or phone call.