Creating your own Rocket Industrial personal account has many benefits:

A major steel distributor and leader in the industry was using standard packaging materials to ship their products, but a Rocket Industrial packaging specialist saw the opportunity to decrease cost while maintaining high packaging standards.

Uncovering cost savings was important for this company to grow as an industry leader. Although their processes were working, Rocket Industrial was able to find solutions that would solve their current objectives.

1. Uncover cost savings

2. Optimize packaging materials

3. Increase banding ergonomics

By providing information on the benefits of switching from steel banding to poly banding, such as injury reduction and cost savings, the customer was eager to change their banding material. A battery-powered handheld bander was also recommended to update the manual process to a semi-automatic process, improving employee ergonomics.

In testing alternative materials, the test lab found that Opus Air pillow film required far less material than the 40lb Kraft paper. Only 15 feet of film was needed to stabilize the load and protect parts.

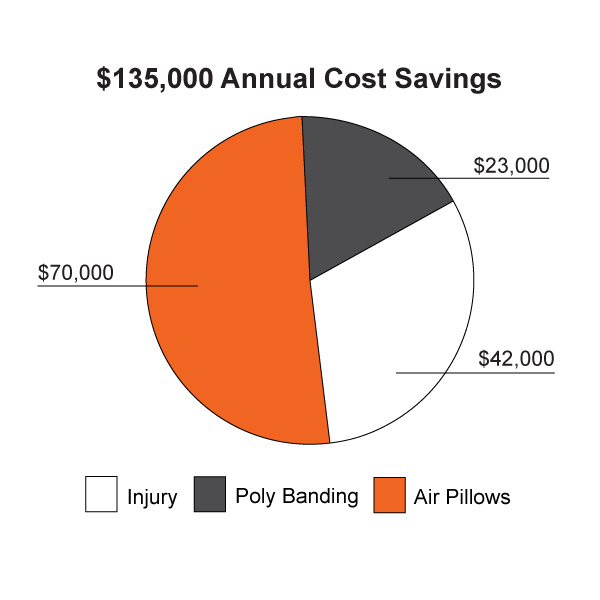

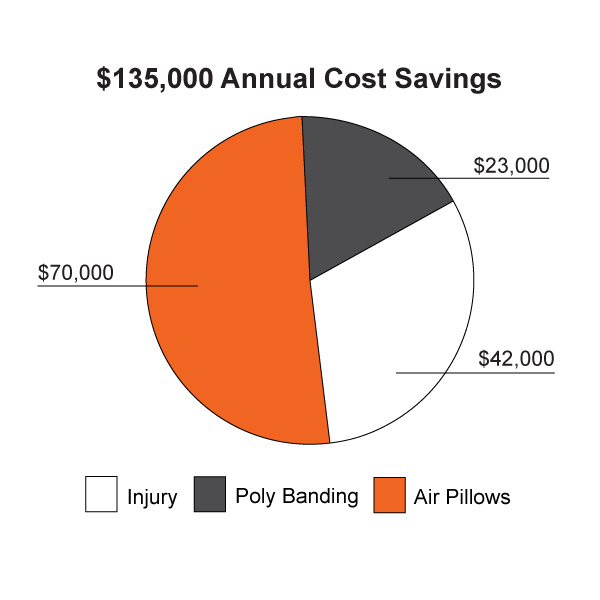

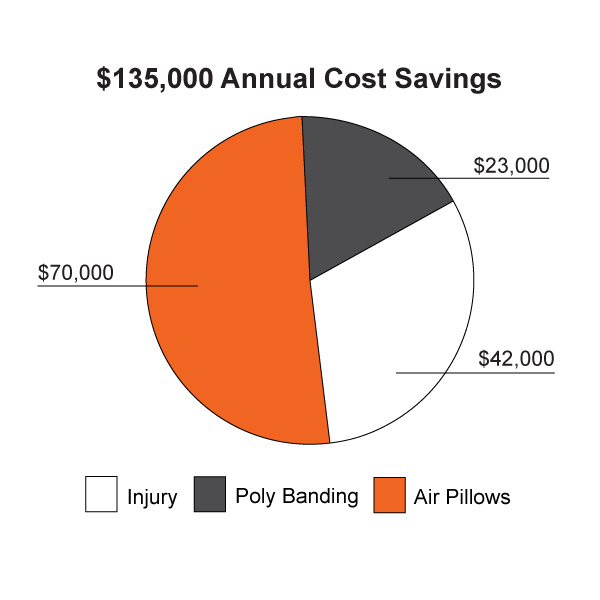

By using poly banding instead of steel, material costs are reduced by $23,000 per year. On average, 2 steel banding injuries happen annually, costing $21,000 each. It is likely that poly banding will eliminate these 2 injuries, resulting in a $42,000 savings each year in injury costs.

Updating void fill from Kraft paper to air pillow film resulted in a cost savings of $70,000.

Overall, Rocket Industrial was able to implement changes that resulted in over $135,000 in cost savings annually for this steel distributor.

Discover ways to reduce your material packaging costs by connecting with our sales reps for a video or phone call.