Creating your own Rocket Industrial personal account has many benefits:

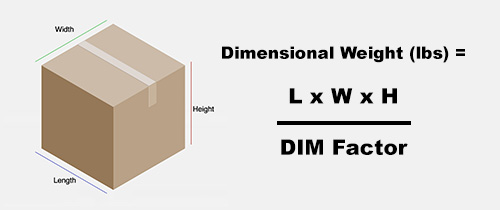

Dimensional weight, commonly known as DIM weight, refers to the package’s volume. It takes into account the size of a package rather than the actual weight. UPS and FedEx apply DIM weight pricing to all packages, so it’s important to know how to properly calculate billable weight and more importantly, how to keep these shipping costs at a minimum.

If a package is high-density, its actual weight is used for shipping costs. Low-density packages are charged based on the space a package occupies on a carrier vehicle at a standard density (dimensional factor) the carrier has determined.

The dimensional factor for UPS and FedEx is currently 139 and the dimensional factor for USPS is 166. Keep in mind carriers typically round weight up, then compare the actual weight versus the dimensional weight to determine the billable weight. The larger weight is the one used for rate calculation.

If you are shipping large, lightweight items, your shipping costs can be extremely affected by DIM weight costs. Aside from trying to negotiate a volume discount with FedEx and UPS, we have some suggestions for other ways to reduce your shipping costs.

Use the Right Sized Boxes

How much air are you shipping? Using a correctly sized box sounds like a no brainer, but it’s not uncommon for eCommerce packages to contain over 50% of empty space. By taking the time to optimize carton size, you can find immediate cost savings.

Rethink Your Materials

While reducing your box size is important, you don’t want to skimp out on protective packaging. On the flip side, it’s also possible that you’re over-packaging your shipments. Finding your ‘packaging sweet spot’, the balance between material cost and damage cost, will assure you the lowest DIM weight.

Test Your Package

Testing your package in real-world conditions to make sure it will effectively endure the shipping process will minimize damage complaints and associated costs. Our engineers can also assess your packaging to see if there are alternative materials you should be using to reduce costs and help you find a better packaging solution. By use of our testing lab, we have been able to reduce DIM weight for customers by as much as 30% in some cases.

Since UPS and FedEx implemented actual vs. DIM weight pricing in 2015, shipping charges have continued to rise every year. If your packages are not fully optimized and using box space effectively, you could be wasting a lot of money on shipping. Our packaging specialists and engineers can help you reduce your shipping costs. Contact us for a free packaging analysis.