Creating your own Rocket Industrial personal account has many benefits:

Manufacturers, distributors, and eCommerce businesses around the world are using automation to increase productivity. Since 1957, Rocket Industrial has been working with our clients to find the right equipment to automate their packaging processes. I sat down with Mike, one of our Automation and Robotics Engineers at Rocket Industrial, for his insight on what it takes to successfully implement automation.

It’s no secret that automation has immense potential to increase productivity. But a lot of manufacturers are still on the fence when it comes to taking the automation plunge. Mike confesses a lot of corporations are afraid of change. “Corporations are afraid of the change automation is going to make in their business. ‘Will it be expensive? Will it do everything we need it to do? Can the expense be justified?’” So how can an automation engineering team help a company take the plunge?

Mike tells me that well before any machinery is selected, he starts the automation process by asking simple questions about what a company does now compared to what they want to do. “We know the questions to ask to help a client get the right solution,” he says. “For example, for a client looking at a case erector, we ask things like, ‘How many boxes do you need to erect in an hour? Do you use 2” or 3” tape? Do you use BC or double-wall corrugate?’ And then we ask them to send samples.”

For every client, Mike creates a detailed spec sheet that goes over every item that could possibly need to be packaged with the new machinery.

Mike grabs his laptop to show me an example of a spec sheet he created for a food manufacturer. The client has 15 different food items that need to be packaged using the same automated case erector, packer, and sealer. “I asked them to tell me each food item’s dimensions, packaging speed, case size, bag size, number of items in a bag. And with this info I created this spec sheet to share with them.” The spec sheet shows the maximum speed and operating goals the client has for the equipment. Mike and a client may go back and forth to revise the spec sheet to make sure it covers all the things the automated machinery needs to do. Only after they’ve got a finalized spec sheet does Mike find or create machinery that will do everything the client needs.

“The spec sheet I create is the recipe for automation,” he says. Whether a client is looking for a simple automated stretch wrapper or a fully integrated high performing packaging line including several pieces of converyorized equipment, someone at Rocket Industrial’s engineering team is going to ask the right questions to make sure the client gets the perfect solution for their job.

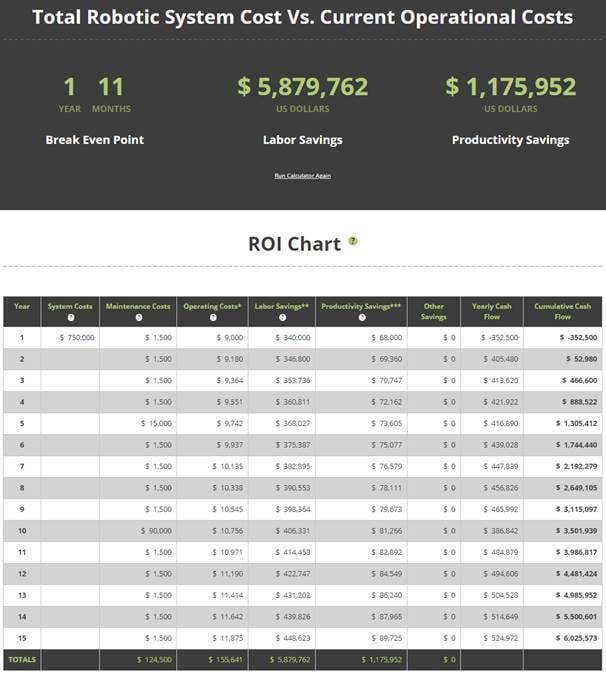

After selecting the right machinery, Mike compares what the machinery is capable of doing against the spec sheet to calculate the client’s return-on-investment (ROI). “Most clients want to see full ROI in two years.” For the example of the food manufacturer, Mike was able to prove the automated machinery he was recommending would give the manufacturer full ROI in one year, even after factoring in machine maintenance and operating costs.

“We’re automation experts,” Mike tells me. “We work with hundreds of industry-leading engineering companies that do everything from designing machines that stack pizza crusts to filling laboratory vials. All our partners design equipment for a specific niche markets. If no one in our network already has the proven solution, we’ll design one.”

There’s no denying the power and flexibility automation gives manufacturers. If you’re ready to take the plunge into automation, we’d like to help you find the right machinery to meet your goals. Contact our automation engineers for more information.