Creating your own Rocket Industrial personal account has many benefits:

Due to a shift in consumer shopping behaviors and heightened expectations from buyers, the ability to effectively package and deliver a product safely is crucial. A product’s packaging is just as much of a representation of a company as the product itself. This is why we have created the Packlytics Packaging Test Lab. With the ability to test packages’ durability by simulating real-world supply chain situations, our engineers will help you protect and optimize your packages.

Along with compression, distribution, climatic, and shock tests, the lab offers custom packaging design and optimization services. Analysis of stretch wrap, pallet pattern, and package size and strength can be done to determine optimal setups to reduce consumption and material costs.

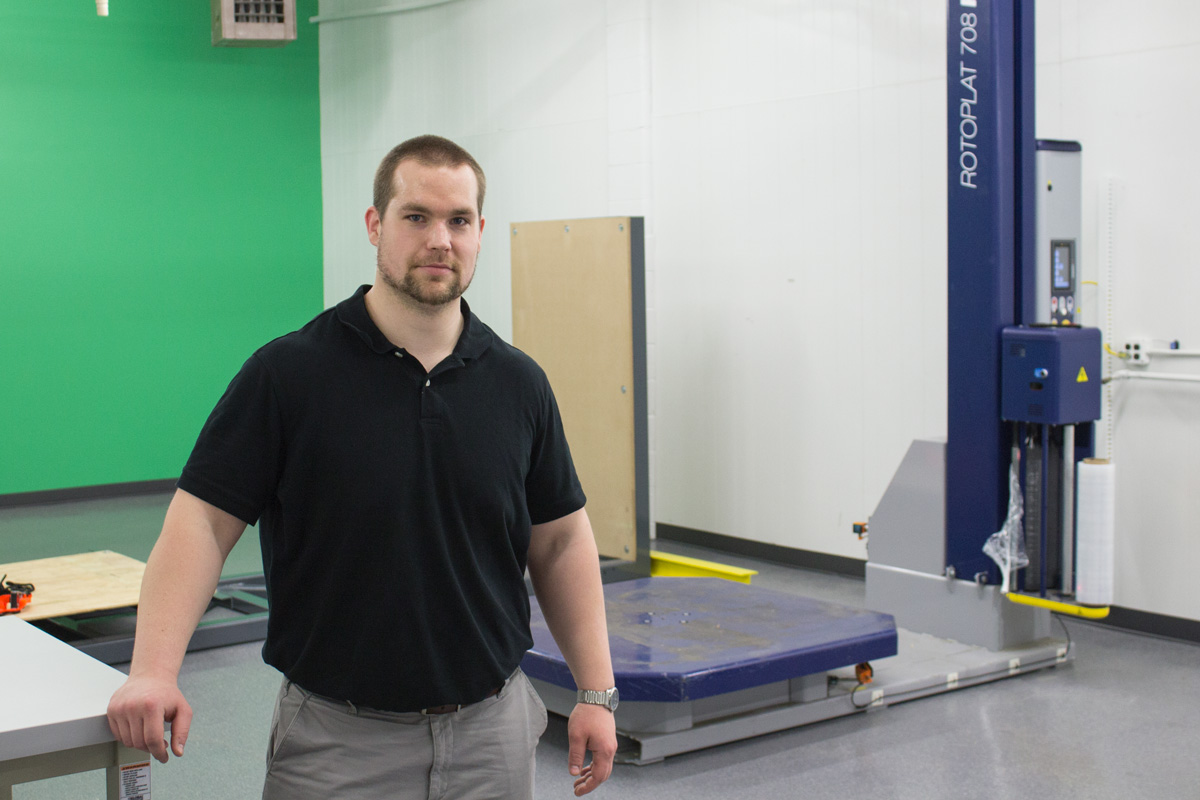

Tim Kretlow is a Packaging Engineer at Rocket Industrial and manages the packaging lab. With an educational background in packaging engineering and years of experience in design testing, prototype construction, and project planning, Tim has an abundance of packaging knowledge. He also has a strong passion for helping clients Package with Less.

What do you enjoy most about being a Packaging Engineer?

I equate a packaging project to a game of chess, if you want to beat your opponent you have to make all the right moves. A win can be as simple as attractive graphics on your retail packaging so consumers choose your product on the shelf or optimizing your stretch film and pallet patterns with the highest cube efficiency to save money on shipping costs. So, brainstorming, planning and implementing all the right packaging moves to arrive at the best solution is what I enjoy most.

What are the main benefits of packaging testing?

Confidence, safety, optimized packaging, insurance, and an opportunity for cost savings.

When should a company consider testing their packaging?

Packaging should be tested before new product launches and when receiving too many complaints from customers about product damage or inefficient packaging. If you aren’t receiving any damage claims, it is a good idea to test still to determine if you can reduce the amount of packaging you are using.

What is packaging optimization and why is it important?

According to a Kissmetrics survey, if your website takes longer than 5 seconds to load on mobile, you’re not living up to 19% of your potential customer’s expectations. So, if your site isn’t optimized, 19% of your potential customers are having a negative experience with your brand before you even say hello.

It’s obvious that everyone prefers a fast loading, optimized website but packaging is a physical experience with your brand before a customer uses your product. You could argue packaging optimization is the most important aspect of your company to get right depending on the scale of your operations. No one wants to work with, buy or experience poorly optimized packaging.

The companies that take the initiative to optimize their retail presence, stretch film usage, protective packaging usage, packaging materials, packaging assembly labor, pallet cube efficiencies, etc. will retain a competitive advantage over their competitors who aren’t making the same efforts.

The Packlytics Lab is an invaluable asset which enables us to have a more detailed understanding of packaging than other suppliers. The lab is also a place for our engineers and designers to flex their creative skills, explore new packaging innovations, and unlock new possibilities, all for the benefit of our customers.

Contact our team if you’re interested in our packaging testing, design or optimization services.