Creating your own Rocket Industrial personal account has many benefits:

Stretch film roping is a stretch wrapping technique that ensures the stabilization of products to the pallet during transport and storage. Roping devices convert a roll of film to a full rope or band, increasing its holding strength, which locks the load to the pallet for better load protection.

Load Protection & Stability

Stretch film roping reinforces the stability of the load to a pallet to ensure the load stays securely attached during transit. Roping creates a “cord” that spirals around the load, reducing the amount of movement during transport.

Breathability for Fresh Products

When using the roping technique to stretch wrap products, the stretch wrap doesn’t have to cover the entire pallet, making it a great option for fresh products. The increased ventilation allows produce and other goods to stay fresher throughout transportation by reducing condensation.

Added Strength to Round or Irregular Loads

Roping when stretch wrapping round products on pallets or irregular loads increases the load integrity. By using roping, the gap between the pallet and/or the products is reduced, creating a stronger hold, and less shifting during transport.

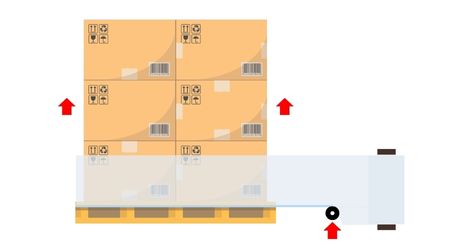

Roping from the Bottom (Rope on Wooden Pallet)

Roping from the bottom of a pallet creates greater cohesiveness between the product and the pallet. This cycle of roping is done by narrowing the film from the bottom and applying the narrow part above the highest wood axis of the pallet.

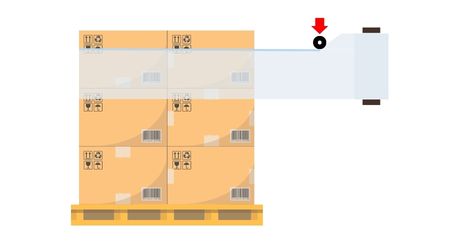

Roping from the Top (Rope in Descent)

This cycle of wrapping is done by wrapping the pallet with an open band of film, then once it is at the top, narrowing the band to create a “cord” and applying it in a spiral down to the bottom. After this, the load is finished with an open band of film. If the product or load is delicate, there can be damage with this method if proper force to load is not used.

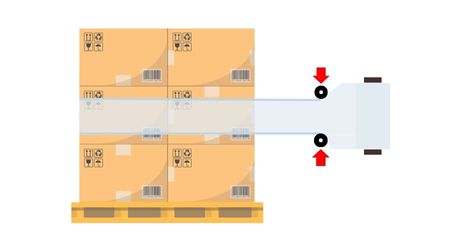

Roping with Double Movement (Double Rope Descent)

Roping with this cycle consists of wrapping the pallet from the bottom up to the top with film with an open band, then narrowing it from the top down to create a double “cord” of film. The rest of the cycle is done with open film. The narrowing of the film can be independent or synchronized with each other.

Robotic Stretch Wrapper

This Robopac S7 portable semi-automatic stretch wrapper can wrap and stabilize palletized loads of any shape, size, and weight.

Semi-Automatic Stretch Wrapper

The Cousins Switch low-profile semi-automatic stretch wrapper features a rapid thread-powered pre-stretch carriage to guarantee proper stretch on every pallet.

Stretch film roping is an effective method for businesses to protect their products during transportation and storage. From the food and beverage industry to construction and manufacturing, roping is an excellent option for reducing damage. Contact us to talk to an equipment specialist to see if roping is right for your application.