Creating your own Rocket Industrial personal account has many benefits:

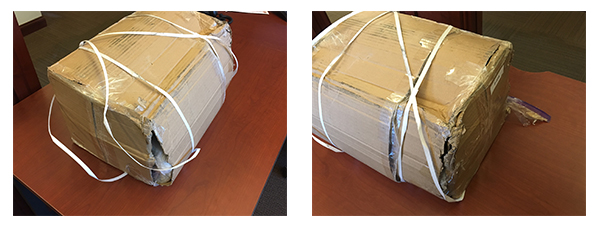

There is nothing more frustrating than receiving a damaged product. It negatively affects the consumer, the business, and the environment. The best way to prevent damage is to properly assess the products being shipped and determine the best packaging options. Investing in the proper packaging to protect your product through the distribution cycle will save you from dealing with excess damage and costs in the future.

By implementing the tips below, your packaging will be so well protected that not even the legendary detective Ace Ventura himself could cause any damage. (Video below for reference!) So, let's dive in and discover how to optimize your packaging to withstand any shipping challenges that come your way.

Selecting the appropriate packaging materials is the most important step for safeguarding your products. Begin by assessing the weight, size, and fragility of the product being shipped. Items may require additional interior cushioning materials like bubble, foam, paper, or corrugated inserts to absorb shocks and impacts. Additional exterior protective packaging such as edge and corner protectors may be needed for extra support.

Shift happens! Load shifting is one of the largest causes of damage during transit. To combat damage from package shifts, it’s crucial to choose the correct carton size. Using oversized boxes can lead to product movement and inadequate support, increasing the risk of damage. On the other hand, undersized boxes may not provide enough space for proper cushioning and protection. Select a box size that allows for protective interior padding and prevents excessive movement.

Proper labeling and handling instructions on the package can greatly reduce the risk of mishandling and damage. If products are fragile, you should clearly mark the packages with appropriate labels, indicating that they require special care during transportation. Additionally, provide any handling instructions such as "This Side Up" or "Do Not Stack" to guide handlers and receivers to ensure the package is oriented correctly.

Using the right stretch film gauge and containment force ensures load stability, reduces the risk of package collisions, and damage from friction during shipment. Containment force refers to the tightness or tension applied to the stretch wrap around a pallet or product. When properly applied, the stretch wrap acts as a protective shield, effectively bundling the items together and securing them to the pallet. By maintaining the right containment force, products are less likely to shift, topple, or experience unnecessary movement during transportation.

The stretch film gauge refers to the thickness of the film. Using the appropriate gauge ensures that the stretch film provides the necessary strength and durability to withstand the rigors of shipping and handling. If the film is too thin, it might tear or puncture, leaving items vulnerable to damage during transit. While a film that is too thick may result in material waste and increased shipping costs.

There are a lot of hazards your products may face along their journey. Damage due to compression, load shifts, and impact are most common but can be prevented. If you’re dealing with an increase in damage rates, our in-house packaging lab team can help. By putting your package through simulated shipping and storage tests, our team can point out failures in your current packaging and recommend changes for a more optimized overall solution.

If you're dealing with an increase in damages and returns, our team is here to help. We've helped many clients reduce their damage rates while reducing their packaging and shipping costs. To get started on an assessment, contact us. We will assess your product and packaging needs to customize a solution that will reduce your damage rates, costs, and packaging waste.