Creating your own Rocket Industrial personal account has many benefits:

Strapping is the most commonly used way to bundle products for shipping. There are many different types of strapping available and it’s important to know the specifications and use for each. A common misconception is that plastic strapping is all the same, but there are extensive differences between the two main materials, polyester (PET) and polypropylene (poly).

Look and feel - Polyester strapping is glossy and smooth. Polypropylene strapping has a matte finish and is usually embossed.

Tension retention – Polyester retains tension over a long period of time. Polypropylene has low retained tension, often losing about half of the applied tension within an hour of being applied. This loss can be accelerated by certain environmental factors as well.

Application methods – Polyester can be applied by manual tools, battery-operated strapping tools, and fully automatic machines. Polypropylene can be applied by hand, with manual tools, battery-operated tools, semi-automatic machines, and fully automatic machines.

Polyester strapping is the more rigid and strong option. Often used as a replacement for steel strapping in many industries. It’s used in heavy-duty bundling applications such as shipping bricks, metals, beverage pallets, and other heavyweight packages. It’s the preferred choice in situations where you need a higher initial and retained tension with less elongation, which allows it to hold a load effectively for longer periods of time.

Polypropylene strapping is economical and designed to be used for light to medium-duty bundling. When people use the term 'poly strapping', they are most likely referring to polypropylene. It’s often used to unitize food products, timber, and packages of a lighter weight. It’s used in situations when you aren’t concerned about high initial tension and only require low retained tension. Polypropylene also offers higher elongation, which is better for loads that are fragile or will be transported for shorter periods.

Embossed vs smooth finishes - The embossed texture provides extra resistance to prevent the strapping from slipping off the carton it's applied to. The smooth finish has no extra coating so the strapping slides easily through strapping tools when being applied.

You also need to assess your current strapping tools. There are no tools that cover every strap size or type. Some tools and machines can be used with any type of plastic strapping and some can only be used with either polyester or polypropylene. (Handheld tools for steel strapping are always exclusive to steel and cannot be applied with a machine.)

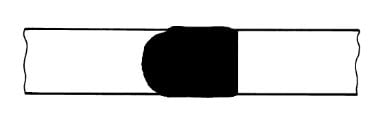

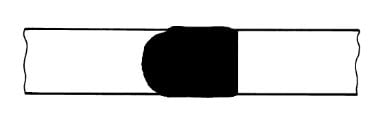

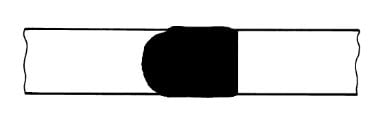

Friction welding, also known as friction joint weld, fuses the two ends of strapping together by a high-frequency movement that generates heat that melts the two surfaces. After this, the two straps are mechanically pressed together to form the seal. As the standard in the industry, friction welds are used by all hand strapping tools and most semi-automatic and automatic strapping machines.

Correct Seal - The seal must be completely welded over the whole width of the strap on a length of ca. 19 mm. Minor quantities of fused plastic may overflow on the sides.

Welding Time Too Short - If the welding time is too short, the plastic strapping will not be welded over the whole width of the strap, making the sealing insufficient. Straps with insufficient seal strength must be removed from the package and resealed.

Welding Time Too Long - If the welding time is too long, the straps become overheated and the fused plastic will overflow on both sides of the straps. Straps with insufficient seal strength must be removed from the package and correctly sealed.

The strapping you choose for your packaging operations will have a huge effect on load containment, so it’s critical to choose the correct type for your application. Since polyester and polypropylene strapping provide specific benefits and advantages over one another, it’s important to fully understand the differences between the two materials and their intended uses to ensure your loads are secure. If you aren’t sure which type of plastic strapping option is best for your needs, contact a packaging specialist for assistance.