Creating your own Rocket Industrial personal account has many benefits:

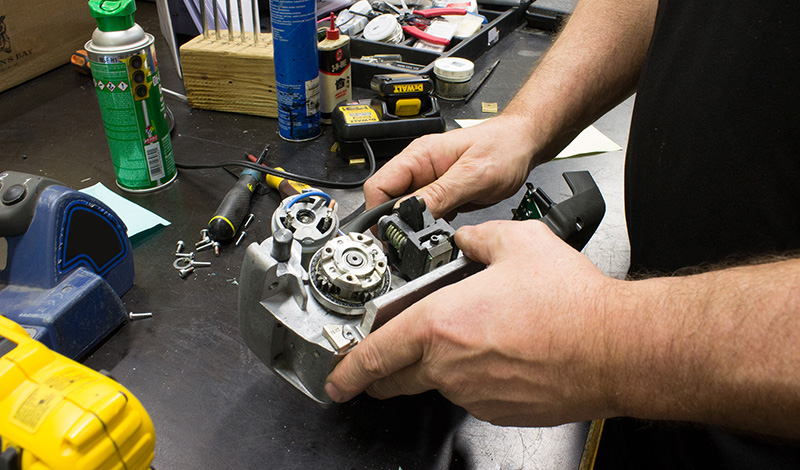

When equipment is not working properly, productivity is affected which results in lost time and money. Preventative maintenance helps to avoid downtime, extends the life of your strapping tools, and assures your tools are performing at their best. Proper maintenance also reduces the risk of injury to operators.

Follow our service team’s maintenance tips to increase the longevity and performance of your strapping tools.

1. Keep Tools Clean - Following a cleaning schedule for handheld strapping tools when they aren’t in use will prevent jams and other issues. At least once a week, make sure to blow the tool out with compressed air to prevent debris and dust buildup. It’s also recommended to clean the tooth plate and tension wheel with a brass cleaning brush after each shift.

2. Charge Batteries - Battery life can be prolonged by charging batteries before storage. It’s also a good habit to get into so you have freshly charged batteries for the next time you or your team members need the tool. Batteries will have to be replaced eventually, with most lasting up to at least 1,000 charges.

3. User Training - Over 50% of repairs are caused by drops and improper use. Misusing the tool can quickly increase wear and tear. Operator training is an extremely important part of protecting your strapping tool.

4. Use the Right Material - Using steel banding is dangerous and will ruin the tensioning, welding, and cutting components. Always use polyester or polypropylene strapping with the right thickness and break strength for your tool.

5. Tool Storage - Having a dedicated place for safely storing your strapping tools can help to prevent damage. It’s good practice to keep your tool on a strapping cart designed for holding and dispensing strapping.

6. Replace and Recalibrate - If a part is worn or broken, make sure you stop using the tool and replace the part right away. We also recommend periodic inspections to recalibrate and test the tool. This can be done as part of a preventative maintenance agreement.

Rocket Industrial is an industry-leading distributor of strapping tools, equipment, and parts. Our in-house service center is able to perform tool quality repairs with minimized downtime. We also have a dedicated parts department that stocks parts for all major strapping tools brands. Contact our service team and we'll get you back up and running in no time.